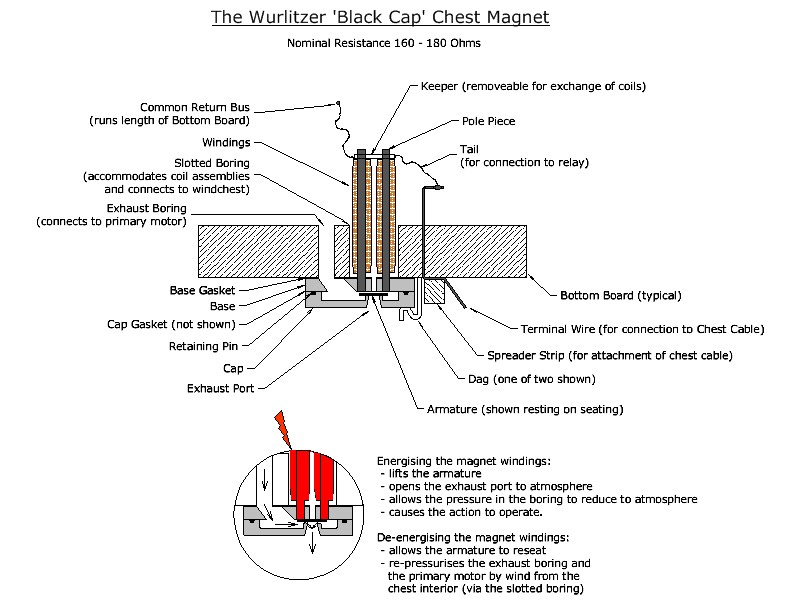

A ubiquitous and essential component of the theatre organ; a form of 3-port 2-way electro-pneumatic valve used to convert the electrical signal(s) from the relay or combination action into a flow of air.

When the magnet is not energised electrically (the ‘normal’ state) the armature is held against the seating in the magnet cap by air pressure from the wind chest, thus covering the exhaust port in the magnet cap. Air from the chest is thus also allowed to pressurise the inside of the pneumatic motor via borings (holes) in the timber structure (usually the bottom board of a windchest) that the magnet is mounted on.

When the magnet is energised electrically (eg by the relay or combination action), the armature is pulled against the magnet pole-pieces. This shuts off the supply of wind from the chest to the pneumatic motor and vents the inside of the pneumatic motor to atmosphere via the uncovered port. Because the motor is mounted inside a windchest which is pressurised, the motor ‘collapses’ due to the pressure differential and the resulting movement used to actuate a further valve or pallet.

When the magnet is energised electrically (eg by the relay or combination action), the armature is pulled against the magnet pole-pieces. This shuts off the supply of wind from the chest to the pneumatic motor and vents the inside of the pneumatic motor to atmosphere via the uncovered port. Because the motor is mounted inside a windchest which is pressurised, the motor ‘collapses’ due to the pressure differential and the resulting movement used to actuate a further valve or pallet.